Polyurethane

Polyurethane is a unique material that offers the elasticity of rubber combined with the toughness and durability of metal. Because urethane is available in a very broad hardness range (eraser-soft to bowling-ball-hard), it allows the engineer to replace rubber, plastic and metal with the ultimate in abrasion resistance and physical properties.

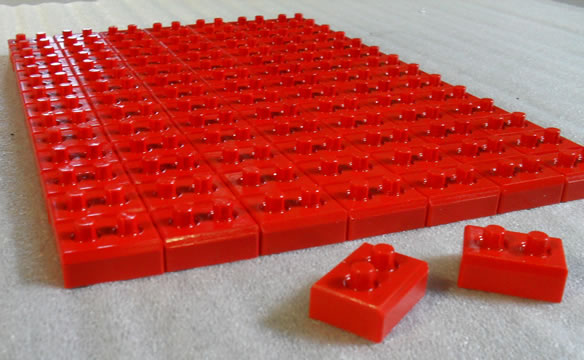

Since polyurethanes have better abrasion and tear resistance than rubbers, while offering higher load bearing capacity, polyurethanes are used in the manufacture of flexible, high-resilience, durable elastomeric wheels and rollers, and hard-plastic parts.

Compared to plastics, polyurethanes offer superior impact resistance, while offering excellent wear properties and elastic memory. Polyurethanes have replaced metals in sleeve bearings, wear plates, sprockets, rollers and various other parts, with benefits such as weight reduction, noise abatement and wear improvements being realized.

Polyurethanes are produced by reacting an isocyanate containing two or more isocyanates groups per molecule with a polyol containing on average two or more hydroxy groups per molecule in the presence of a catalyst.

The properties of a particular polyurethane are greatly influenced by the types of isoyanates and polyols used to make it. Long, flexible segments, contributed by the polyol, give soft, elastic polymer. High amounts of crosslinking give tough or rigid polymers. Long chains and low crosslinking give a polymer that is very stretchy, short chains with lots of crosslinks produce a hard polymer.

The choices available for the isocyanates and polyols, in addition to other additives and processing conditions allow polyurethanes to have the very wide range of properties that make them such widely used polymers.

Advantages of Polyurethane

Abrasion resistant

Parts made of polyurethane will often outwear other materials when severe abrasion is a factor. It has been proven to be vastly superior to rubber, plastics and metal in many applications.

Oil and solvent resistant

Polyurethane has excellent resistance to most oils, solvents, fats and greases.

Load bearing capacity

Polyurethane has a higher load-bearing capacity than any conventional rubber. Because of this characteristic, it is an ideal material for load wheels, heavy-duty couplings, metal-forming pads, shock pads, expansion joints and machine mounts.

Tear resistant

The tear-strength of polyurethane is far superior to rubbers. As a result, urethane is often used as drive belts, diaphragms, roll covers, cutting pads, gaskets and chute liners.

Weather resistant

Polyurethane has outstanding resistance to oxygen, ozone, sunlight and general weather conditions.

Excellent noise abatement properties

Hard polyurethanes are now being used as gears in products where engineers desire sound reduction. The soft urethanes are used to replace rubbers for improved sound/vibration dampening.

Flex-Life

Most formulations offer extremely high flex-life and can be expected to outlast other elastomer materials where this feature is an important requirement. Dust boots, bellows, diaphragms, belts, couplings and similar products are made from urethane for this reason.

Electrical properties

Polyurethane has excellent electrical insulating properties and is used successfully in many moulded wire and cable harness assemblies.

Heat and cold resistant

Continuous use above 225°F is not recommended nor is polyurethane recommended in hot water over 175°F. At low temperatures, polyurethane will remain flexible down to -90°F. A gradual stiffening will occur at 0°F, but will not become pronounced until much lower temperatures are obtained.

***All information provided is intended for reference or informational purposes only and should not be considered to be either complete or exhaustive in nature. Please contact us directly should you require specific information regarding any of these compounds.